Insects are the most diverse species of animals living on earth. Apart from the open ocean, insects can be found in all habitats; swamps, jungles, deserts, even in highly harsh environments such as pools of crude petroleum (Imms, 1964). Insects are undoubtedly the most adaptable form of life as their total numbers far exceed that of any other animal category. The majority of insects are directly important to humans and the environment. For example, several insect species are predators or parasitoids on other harmful pests, others are pollinators, decomposers of organic matter or producers of valuable products such as honey or silk. Some can be used to produce pharmacologically active compounds such as venoms or antibodies. Less than 0.5 percentage of the total number of the known insect species are considered pests, and only a few of these can be a serious menace to people.

Insect pests inflict damage to humans, farm animals and crops. Insect pests have been defined by Williams (1947) as any insect in the wrong place. Depending on the structure of the ecosystem in a given area and man's view point, a certain insect might or might not be considered a pest. Some insects can constitute a major threat to entire countries or a group of nations. One prominent example is the tsetse fly that puts about 100 million people and 60 million head of cattle at risk in sub-Saharan Africa due to the transmission of trypanosomiasis (ICIPE, 1997).

Herbivorous insects are said to be responsible for destroying one fifth of the world's total crop production annually. One major reason why there are pests is the creation of man-manipulated habitats, that is, agroecosystems that fulfil man's needs, where crops are selected for their large size, high yield, nutritious value, and clustered in a confined area. This does not only satisfy man's demand, but provides a highly conducive environment for herbivorous insects at the same time. In the process of artificially selecting suitable crops for human consumption, highly susceptible plants for infestation by insects are also selected. Many of the crop varieties that were developed during the past 30 years produced high yields, but, they also had poor storage characteristics (Kerin, 1994). Insect pests are capable of evolving to biotypes that can adapt to new situations, for example, overcome the effect of toxic materials or bypass natural or artificial plant resistant, which further confounds the problem (Roush and McKenzie, 1987).

Provision of food has always been a challenge facing mankind. A major cornerstone in this challenge is the competition from insect pests. Particularly in the tropics and sub-tropics, where the climate provides a highly favourable environment for a wide range of insects, massive efforts are required to suppress population densities of the different pests in order to achieve an adequate supply of food. In the developing countries, the problem of competition from insect pests is further complicated with a rapid annual increase in the human population (2.5-3.0 percentage) in comparison to a 1.0 percentage increase in food production. Taking into consideration sudden problems caused by drought in places such as Africa, considerable losses of agricultural products add a serious burden to people's daily life.

The introduction of alien pests into new habitats due to the global increase of trade and transport causes another dilemma. When a pest is carried to a new geographical area, its natural enemies that keep it in check in its aboriginal home are normally left behind. This situation, in most cases, may lead to critical complications. One major example is the introduction of the spotted stemborer, Chilo partellus Swinhoe, into Africa coming from Asia early this century, that is now responsible for significant losses in maize and sorghum in many parts of Eastern and Southern Africa. The exotic pest may have also led to partial displacement of the native African stemborers such as Sesamia calamistis Hampson, Chilo orichalcociliellus Strand and Busseola fusca (Fuller) (Overholt et al., 1994; Kfir, 1997). Recent estimates of yield losses due to stemborers alone in sub-Saharan Africa are in the neighbourhood of 20-40 percentage of the potential yield (Youdeowei, 1989; Seshu Reddy and Walker, 1990). These losses indicate the importance of stemborers as a limiting factor affecting crop productivity in Africa.

Prostephanus truncatus (Horn) is another exotic storage pest native to Mexico. It has recently been introduced to Africa (McFarlane, 1988; Pike et al., 1992), where it is currently a more destructive pest of stored maize and cassava than in its native Central America (Dick, 1988). P. truncatus attacks maize before and after harvest. Adults bore into the maize cob causing severe damage and weight loss. In Tanzania, maize losses of up to 35 percentage may occur due to P. truncatus in 5-6 months if improperly stored (Mallya, 1992), and up to 60 percentage after nine months of storage (Keil, 1988); a situation that may result in a serious famine.

Subsistence grain production is essential for the growing population of Africa. Maize is the main staple food in sub-Saharan Africa. An area of 20.7 million hectares is planted to maize in the whole of the African continent, with an average annual production of 29 million tons (Christopher et al., 1996). In sub-Saharan Africa, three quarters of the total production of maize is consumed as human food, which is also the case with other cereals such as sorghum and millet. The area planted by sorghum in Africa accounts for 21.8 million hectares with an average yield of 0.78 ton/ha, while 18.5 million hectares are planted with different types of millet (finger millet, pearl millet, presom and foxtail millet), yielding an annual average of 0.61 ton/ha (FAO & ICRISAT, 1996). Several factors are responsible for this considerably low level of production, of which insect pests are chiefly involved. In the Kenyan highlands, total losses due to pests in maize were estimated at 57 percentage, with insect pests being more important than diseases (Grisley, 1997). In Zimbabwe, grain damage of 92 percentage in stored maize was reported due to insect pests. Treatment with malathion reduced the damage by only 10 percentage (Mutiro et al., 1992). In Namibia, up to 30 percentage losses in pearl millet production can take place due to the bush cricket, Acanthopolus discoidalis (Wohlleber et al., 1996).

Root crops, such as cassava and potatoes, and pulses, which are legumes grown for their edible seeds, provide the basic source of carbohydrates and protein for people in many parts of the African continent. The area planted to cassava in sub-Saharan Africa is estimated to be 8.9 million hectare producing 72 million tons annually (Sengooba, 1994). Insect pests, in addition to fungal diseases, are responsible for 50 percentage damage in cassava (Yaninek,1994). Pulses, described as the poor man's food (Aykroyd & Doughty, 1982), are widely planted in west Africa. Cowpea, for example, is grown extensively for seeds, pods and leaves in about 15 African countries, among which Nigeria and Niger produce half of the world's total crop (Pandey & Westphal, 1989). Cowpeas are attacked by a complex of insect pests, particularly towards the end of the planting season. In storage, the bruchid, Callosobruchus maculatus, causes the major losses. Infestations of stored cowpeas can be as high as 90 percentage in markets and in village stores (Alebeek, 1996).

Almost 80 percentage of these food crops are produced by small scale farmers and stored on the farm (Wongo, 1996). Due to poor storage structures and conditions, severe losses in quality and quantity of stored food are inflicted annually. Quantitative assessment of losses is difficult because of the high variability in infestation from year to year, however, estimates from several countries in Africa indicate an intense impact of insect pests (see table 1). In Kenya, the National Food Policy Document reported up to 30 percentage destruction of harvested maize due to pests during storage and handling (Wongo, 1996). In West Africa, up to 100 percentage damage to cowpeas may happen in a few months after storage due to the infestation of C. maculatus (Lienard & Seck, 1994). Such high levels of losses continue to take place because of poor threshing, cleaning, drying and storing techniques.

After the crop is harvested, it undergoes several operations that, if improperly done, may result in serious losses (see Laubscher & Cairns, 1983; Giga, 1987; Jonsson & Kashweka, 1987; Gwinner et al., 1996). As a start, it should always be recognised that an intact grain is an essential item for successful storing. Cracked or broken grains provide an entry point for infestation by insects and moulds during storage. Damage to grains may happen due to improper application of post-harvest practices such as threshing, drying or transporting (see Rowley, 1984; Dadzie, 1994; Simone et al., 1994). Threshing, which is the removal of grain from its protective case, may inflict a degree of physical damage to the grains (Laubscher & Cairns, 1983; Swamy & Gowda, 1987; Wilson, 1987). Millet for example is sensitive to threshing (see Appert, 1987; UNIFEM, 1988), therefore it is stored unthreshed and pounded on a daily basis according to the farmer's needs. Wongo & Pedersen (1990) found that threshed sorghum grains were more susceptible to Sitophilus oryzae than unthreshed grains. Maize, specially in wet regions, is normally stored in its shucks, but with modern varieties shucks are removed. In this case, proper care should be taken and insect repellents or antifeedants should be applied.

Crop transportation is another process where losses are common. Physical damage, grain spilling or deterioration might occur, specially if transport is prolonged. However, such losses can be avoided through proper packing, loading and handling of the crop (see Youdeowei & Service, 1983; Gwinner et al.,1996)

Crop products are eventually stored for varied periods of time depending on market demand, size of production and the farmer's needs. Storage is the most important and critical post-harvest operation. Deterioration of the grain quality during storage can be due to improper storing conditions, which leads to contamination with fungi or insect infestation. A primary source of infestation of the stored crop is the field where the crop has grown. In many cases, infestation starts in the field. In the case of the potato tuber moth (Phthorimaea operculella), adult females lay eggs on the plant leaves early in the season before the crop is harvested. With cowpeas, only a 1-2 percentage initial field infestation by C. maculatus may result in 80 percentage of the pods attacked after 6-8 months in storage (Youdeowei, 1989). The problem can be more complex if the crop is planted or stored near by old granaries, which is the case with most of Africa's small scale farmers. The infestation can easily move to and from storage sites. Moreover, using the same bins year after year without proper hygiene, provides a continuous chain of infestation. Insects can hibernate or even continue to feed on wooden structures of the store or hide between holes and cracks in the walls. They can then reinfest the new crop in the same store and resume feeding.

Storing generally leads to a degree of quality change in the product due to seed's respiration, which depletes seed's nutrients over time (see Hodges, 1989; Piergiovanni et al., 1993; Kadlag et al.,1995). Combined with attack by insects and mould, rapid deterioration of the crop quality might occur. In case of whole cereal grains, a rise in temperature is expected due to respiration, which might also occur due to insect or fungal activity. Heating leads to moisture condensation in cool areas within the grain mass. This in turn encourages further fungal growth and insect infestation (see Appert, 1987; Imura & Sinha, 1989). The exact safe moisture contents varies slightly between the different grains, however, moisture should not exceed the range of 12-13 percentage for most cereals. For pulses, intact dry grains are relatively resistant to damage, but moist, broken, split or shelled pulses are highly sensitive to infestation. On the other hand, very dry pulses with a moisture content less than 11 percentage have a breakable seed coat that cracks easily (see Youdeowei & Service, 1983; Gwinner et al., 1996).

In most parts of sub-Saharan Africa, harvesting of maize and other cereals is done by hand. Farmers have to wait until the crop is sufficiently dry. Some farmers leave the plant standing in the field until it dries up. This, however, might not be adequate as the longer the plant stays in the field the riskier it gets. Infestation by post-harvest pests are mainly encouraged during this stage. In Zimbabwe, for example, four months may elapse after physiological maturity of maize and before harvesting and treating the crop, during which 9.1 percentage of potential yield is lost due to attack by pests (Mvumi et al., 1995). Alternatively, maize might be picked up when it is still in need for drying, specially in the rainy regions of the tropics. In this case, quick drying should take place as soon as the crop is harvested. In drier areas, getting rid of excess moisture may be much easier than in wet tropical regions.

Traditional methods usually provide cheap and feasible ways of post-harvest handling of the crops. Farmers adopt different methods for grain drying depending on the farmer's environment and socio-economic status. Sun drying, for example, is a widely practised method wherever there is enough sunshine and little rains. In this case, grains are spread on wide plastic sheets to isolate the crop from soil dampness, and to make it feasible to move the crop later after drying or in case of sudden rains. Continuous checking should be done on the stored crop to investigate the moisture content, presence of pests, moulds or deteriorating grains. However, farmers may use fire to dry the grains, specially in the rainy areas of the tropics where sun drying is not applicable. A more appropriate method is the use of "bush dryers", where air is heated up by burning wood and then circulated through metal tunnels. Grains are spread on grids on top of the tunnels. One disadvantage with this method is that temperature might not be well controlled. Caution should be maintained as abrupt or overdrying will cause loss of nutrients or germination capacity. Temperature should not exceed 430C for cereal seeds and 350C for legumes. Higher temperatures (up to 600C) can be used to dry cereals meant for consumption (see Gwinner et al., 1996).

A more controlled sun drying method is the use of solar dryers, where the product is spread on grids and placed inside a cylindrical metal tunnel (see Mbengue et al., 1987; Odogola, 1994). The tunnel is painted black to absorb heat and contains an opening from one side to let in air. A chimney is provided on the other end to serve as air and moisture outlet (see Ekechukwu & Norton, 1997). Inflow of air can be regulated through the entrance, thus adjusting air temperature inside the tunnel. Solar dryers are adequate devices, specially for smaller quantities of products, in which grains are fairly well protected against adverse weather conditions and the invasion of insect pests. Continuous improvements in the structure and utilisation of solar dryers are taking place in Africa (Bechis et al., 1997; Ekechukwu & Norton, 1997), however, the use of solar dryers does not seem to be as wide spread as other drying methods in Africa, probably due to the relatively high cost and their limited capacity. Solar dryers may not be applicable in highly humid or cloudy areas of the tropics (but see Asota, 1996; Ekechukwu & Norton, 1997).

1.2.1 Small scale storage structures

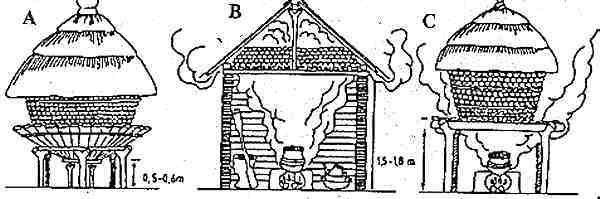

At a small farming scale, grains are stored traditionally in different styles of containers, depending on the farmer's socio-economic status and his environment (see Audette & Grolleaud, 1983). Structures used traditionally are often inexpensive and environmentally motivated. Subsistence stores may be made out of clay, thatch, mud, wood or stones (see Rukuni et al., 1988; Bani, 1991). Larger granaries, meant for storing large quantities for longer periods of time, may be built with more permanent structures, as in case of metal silos or wooden granaries with iron sheet roofs. Open storage is probably the most common system used traditionally in sub-Saharan Africa, specially in the humid areas, where the crop is harvested with high moisture contents and continues to dry in the store. Open structures can simply be wooden platforms on stakes or posts, on top of which the crop rests either in heaps or regular layers. A straw roof is usually provided to protect the crop from rains. Farmers may use fire underneath this structure for insect control and to provide further drying. An even simpler method is hanging the crops in frames or sheaves to tree branches, which is applicable for smaller quantities that would be rapidly consumed. Open storage provides natural ventilation and allows for further drying of the crop. It also discourages development of fungi due to continuous aeration. However, open storage does not provide adequate protection against insect pests or other animals such as birds and rodents (see Appert, 1987; Gwinner et al., 1996).

A more protected storage system, adequate for the semi-arid regions of Africa, is the use of "cribs" (see FAO, 1985; Appert, 1987). Cribs are wooden four-cornered structures with ventilated sides. The sides are covered with woven straws, grass stalks or wire netting materials and a thatch roof is provided on top. An elevated floor is made out of wooden branches and attached to the posts about 50 cm above ground. This structure proved to be excellent for drying maize in Nigeria, where it is made out of bamboo and used mainly for drying and storing maize cobs. It is also used in other humid regions of sub-Saharan Africa with considerable success.

In the dryer regions of Africa, where crops can be harvested with satisfactory low moisture contents, more closed types of granaries are used. Different sizes and types of such closed structures are widely spread in Africa, where they can be made out of mud, woven straws or a mixture of mud and chopped straws (see Figure 1). Farmers in the semi-arid zones of sub-Saharan Africa, such as Mauritania, Senegal, Mali, Niger and Chad, use a mixture of clay or mud and straw called "Banco" to build concealed granaries. Banco granaries can be four-cornered, spherical, with a straw roof containing a protecting lid, or in the shape of a cone with the tip pointing downwards and resting on a foundation of stones. Grains inside these banco granaries are well protected against rains and the invasion of insect pests. If the structure is well built and maintained, insect pests would find it very difficult to survive inside due to the lack of oxygen. Granaries made out of mud or clay provide a cool environment that keeps grains viable for germination. This structure is appropriate for dryer areas of Africa where sudden heavy rains are unlikely. However, Banco granaries require good maintenance such as filling cracks, which are common with mud structures, sealing holes or fissures and thorough cleaning.

In some parts of Africa, such as Morocco, Mauritania, Nigeria, Chad, Cameroon and Somalia, grains are stored underground (see Bartali et al., 1990; Bakhella et al., 1993; Lemessa & Handreck, 1995), however, it is not as widespread in the African continent as it is in India. In India, an underground pit, 2-2.5 meters in depth, is dug in soil and a fire may be lit to dry up the walls. Afterwards, bricks can be used to build a wall or otherwise walls are plastered with clay and the bottom is covered with chopped straws or husks. The pit is sealed from the top with a roof at or slightly above ground level. Underground storage provides excellent protection to the stored products specially in arid areas, however, it may also be applicable in rainy areas provided that the entry of both ground and rain water is prohibited through careful cementing and lining of the walls (see Mantovani et al., 1986; Smith & Sanders, 1987).

Smaller amounts of grains can be stored in different types of containers, calabashes, clay pots, sacks or woven baskets (see Kennedy & Devereau, 1994). Such containers allow for frequent consumption of the product on a daily or weekly basis. Baskets can be made out of local plant materials and may themselves be placed inside the granary or in the farmer's house. Jars made out of clay are also used to store beans or cowpeas, as in west Africa, where they are usually placed inside the farmer's house. Jars have a narrow opening and are hermetically sealed with a stone on top. Hermetic storage leads to depletion of oxygen and accumulation of carbon dioxide inside the container, which eventually lead to elimination of insect pests (see Mantovani et al.,1986).

Traditional storing systems can be satisfactory if built and maintained properly. Recently, farmers in sub-Saharan Africa started adopting newer storing systems. Concrete or metal silos, with capacities up to 5 tons of cereals, are now used in many parts of the continent among medium scale as well as large scale farmers. The use of plastic sacks, bag storage, prefabricated iron halls and flexible plastic silos are increasingly gaining ground among farmers for short-term storage (see Peterson & Simila, 1990; Compton et al., 1993; Bartali, 1994). Large warehouses and metal silos, run under state control, are common among co-operatives and traders. Centralised storing has emerged due to the change in the social and economic structures of the farm community. Centralised stores can be large metal constructions that may contain up to 3000 tons of produce. Though the adoption of bulk storage has led to a significant decrease in the amount of food stored by small scale farmers for emergencies, it does form an important function in sustaining sufficient food supply. Bag storage in large warehouses is a suitable system for bulk storage in the tropics and sub-tropics (see Carvalho et al., 1994; Cabrera & Lansakara, 1995)

1.2.2 Warehouses

Warehouses are practical and appropriate structures for storing and protecting food crops (see Cabrera & Lansakara, 1995; Gwinner et al., 1996). Stored crops can be easily maintained and treated, transported to and from the warehouse and regularly checked for insect or fungal infestation. Good and effective warehouses are simple four-cornered buildings with ample ventilation. It is always preferable to build a concrete floor one meter above the ground level to guarantee adequate isolation of ground moisture or water flooding. Concrete walls are the most suitable if properly built with no cracks or holes to discourage insects. Aluminium sheets provide adequate roofing and are better used than corrugated iron to avoid raising of temperature. Appropriate and controlled ventilation is essential for successful storage in warehouses. Lower and upper ventilation openings for inlet and outlet of air should be fitted with wire mesh or grids , but with the possibility for sealing to allow for secure pesticide fumigation. A well designed and maintained drainage system is important for preventing rain water from affecting the stored produce (For more details on warehouse structures see Bisbrown, 1992).

Sanitation in stores is a key factor for preserving products in good condition (see Suss & Locatelli, 1993; Rotundo et al., 1995). Sanitation is a simple practice that can save the product from losses due to infestation. Sanitation starts with the removal of any unnecessary objects from the store. Thorough cleanliness of the store through sweeping, removal of left overs and prompt burning the trash is essential before receiving in a new lot. Clearing the surroundings is a recommended practice, in which grasses, shrubs and any kind of vegetation around the building should be cut down thoroughly. The produce should be checked on a regular basis and the presence of any insect pests, rodent debris, damaged cobs or rotten grains should be recorded and dealt with accordingly (see FAO, 1985; Cruz & Diop, 1989; Vinuela et al., 1993).

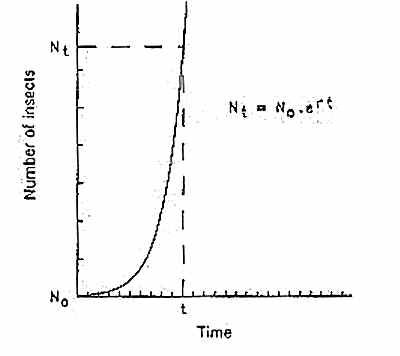

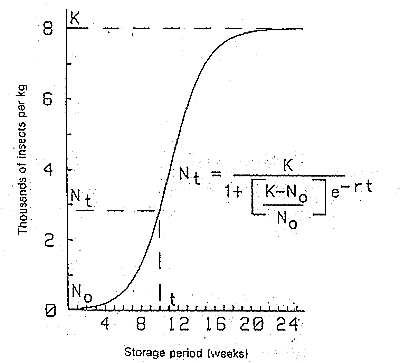

Insect pests inflict their damage on stored products mainly by direct feeding. Some species feed on the endosperm causing loss of weight and quality, while other species feed on the germ, resulting in poor seed germination and less viability (Malek & Parveen, 1989; Santos et al., 1990). Thus, due to damage done by insects, grains lose value for marketing, consumption or planting. Most storage pests are able to increase in numbers drastically within a relatively short time. At an early stage of development, population growth takes the "exponential" form, where the number of insects at a given time can be expressed by this equation: Nt= N0 ert , where Nt is the number of insects at time t, N0 is the original number of insects and r is the rate of intrinsic increase of the population (Figure 2). However, this pattern of growth would eventually reach an upper plateau due to depletion of food and intraspecific competition (Figure 3). In that case, the number of insects at any given time can be expressed by the equation:

Nt= K /(1+((K- N0)/N0) e-rt)

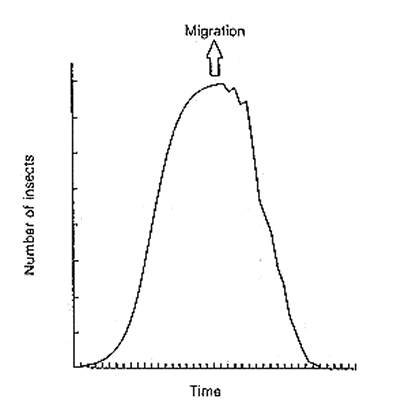

where K is the maximum number of insects that the environment can support, which is also known as the "carrying capacity" of the environment. In grain stores, K is not constant and will decrease as the food is consumed. Eventually, the insect population will start to decline due to the decrease in food availability and competition among individuals, which is when a proportion of insects will have to migrate and search for other food sources (Figure 4).

In addition to direct consumption of the product, insect pests contaminate their feeding media through excretion, moulting, dead bodies and their own existence in the product, which is not commercially desirable. Damage done by insect pests encourages infection with bacterial and fungal diseases through transmission of their spores (Cravedi & Quaroni, 1982; Ekundayo, 1988; See also Dunkel, 1988). The presence of insects also raises the product temperature, due to their feeding activity, resulting in "hot spots" (see Appert, 1987; Mills, 1989). These spots in turn lead to concentrating of humidity within the product, thus stimulating seed deterioration and further fungal activity. There are a wealth of studies examining the effect of insect pests on grain contents. In Brazil, for example, Santos et al. (1990) showed that the presence of Sitophilus zeamais and Sitotroga cerealella in maize grains led to a reduction in germination with increasing developmental stage of the insects, from 13 percentage at the egg stage for Sitophilus zeamais and 10.9 percentage for Sitotroga cerealella, to 93 percentage and 85 percentage at the adult stage for S. zeamais and S. cerealella respectively. In India, Sudesh et al. (1996 b) found that infestation of wheat, maize and sorghum grains with single or mixed populations of Trogoderma granarium and Rhyzopertha dominica resulted in substantial reductions in the contents of total lipids, phospholipids, galactolipids, and polar and nonpolar lipids, while Jood et al., (1995) recorded a significant decrease in essential amino acids in the same crops due to mixed infestation with the same two pests, with maximum reduction found in methionine, isoleucine and lysine. Similarly, Kumar et al., (1996) recorded a substantial reduction in starch in parboiled cassava chips due to infestation with Sitophilus oryzae and Rhyzopertha dominica as compared to the uninfested chips. In Nigeria, Okiwelu et al. (1987) recorded high level of moisture, combined with a decrease in germination ability of maize due to infestation by Sitophilus zeamais, while Mbata (1994) showed that infestation of bambarra groundnuts (Vigna subterranea) with Callosobruchus subinnotatus reduced seed viability and increased free fatty acids and peroxides, which are indices used in measuring biochemical deterioration.